Individual components and systems to which patients entrust their lives. Justifiably the companies in the medical industry place the highest demands on quality and reliability, also on their partners in the supply chain.

We develop and manufacture subassemblies in a material mix out of sheet metal and plastic with finishing. Our know-how in the manufacturing of multi-component assemblies as well as finest breakthroughs and structures is of great benefit to us in the field of medical technology.

Patients all over the world trust in the proper function of medical components and systems. Our customers supply the market with high-quality devices which are for example used in the areas of emergency ventilation, intensive care, patient monitoring, surgical procedures and in-patient treatment.

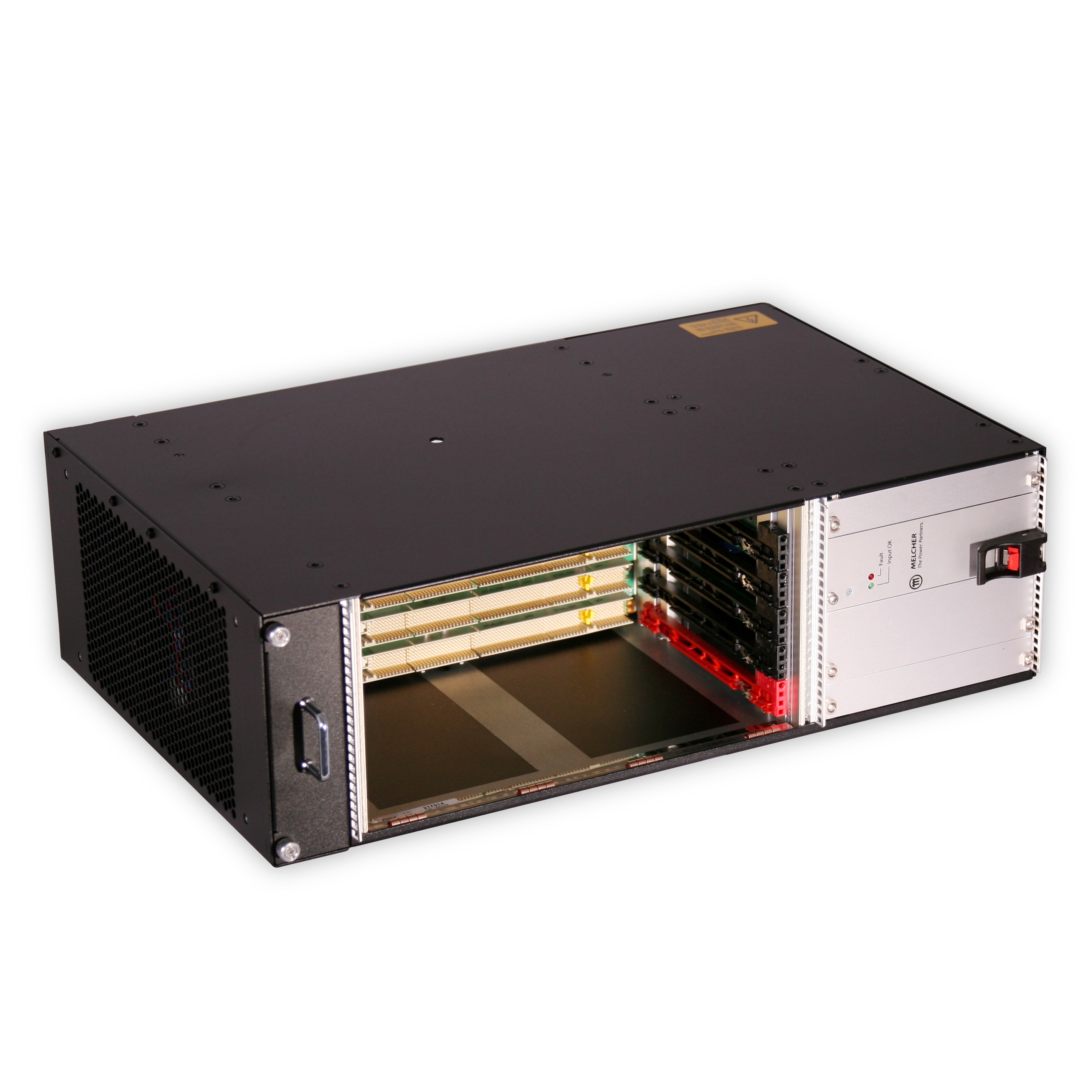

The POLYRACK TECH-GROUP supplies parts or assemblies which built the mechanical device basis or which are used as design covers. We accompany our customers from the early stages of development, through the design and prototyping phase, up to the series production phase of their products. We consult you across technologies in sheetmetal, plastics and die cast components, since the best solution often develops out of the mix of these technologies. The finishing of your parts with technical or decorative surfaces completes our portfolio.

We support you in all phases of your development process related to the technical layout and construction of your mechanical assemblies as well as by providing advise across potential manufacturing technologies from our portfolio. The production of the first prototypes and advanced integrational samples for theverification of the funcionality complete our portfolio.

It is our declared target to define the perfect product solution considering all technical requirements as well as the planned cost structure, together with our customers.

An important element for a succesful product are stable and technologically feasible processes which provide a reliable production. Therefore we consult you with an interdisciplinary project team, which is complemented by experienced production technologists. With this team we focus on the Design for Manufacturing from the first day of development until the series production.

An important element for the product success are the implementation, of first article inspection and qualification of efficient and stable processes which provide a long term production of your product. All production processes are initially qualified and verified upon the series start-up.

With our cross technological business model we are your competent partner for the long-term production of single parts, components and complex assemblies of your product in series. You decide what technolgies and services you wish to use.